Special Features

- Stainless steel version with large filter area and filter back wash

- With 1,2 m² or 1,6 m² filter for dust containing materials like tea powders

- Conveying duct DN 38, 50, 65 or DN 80

- Vacuum pumps for different conveying capacities up to 3000 kg/hr. and more

- Programmable microprocessor control with many options

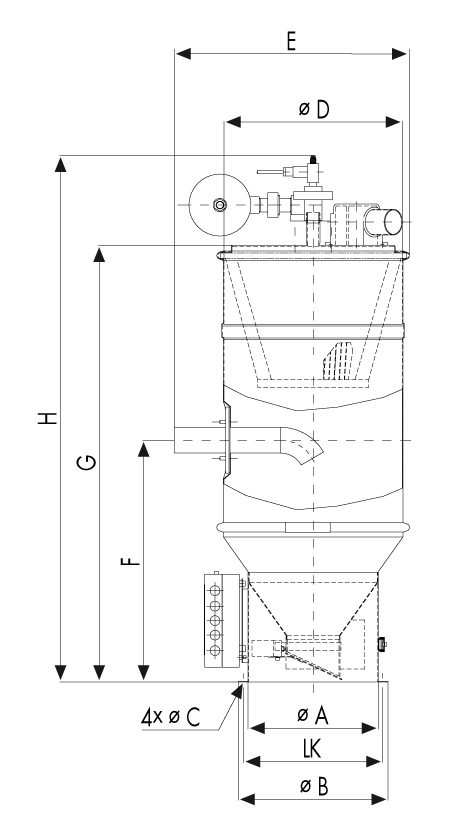

| Dimensions |

øA = 250 øB = 290 øC = 4x ø8,5 øD = 345 E = 456 F = 468 G = 842 H = 1019 øLK = 269 |

|

| Optional Extra Equipment |

• ConPuls suction impulse conveying |

|

| Other Components |

• Mobile-Container to handle bulk materials for all industries |

|