To cater for applications in the fields of medical and health care products, the machine conforms to the relevant hygiene standards. On request, it can be equipped with a containment RABS for air quality conditioning in the process chamber.

Special features of FS 200

– Heat sealing or ultrasound technology

– Lower tool working independently from rotary indexing table

– Suitable for a range of tools with accurate sealing force adjustment

– Individual temperature control for each sealing tool

– Knee lever sealing system with servo drive

– Upgradeable with laminar flow unit in filling area

– Suitable for integration of gas-tight area for filling under shielding gas

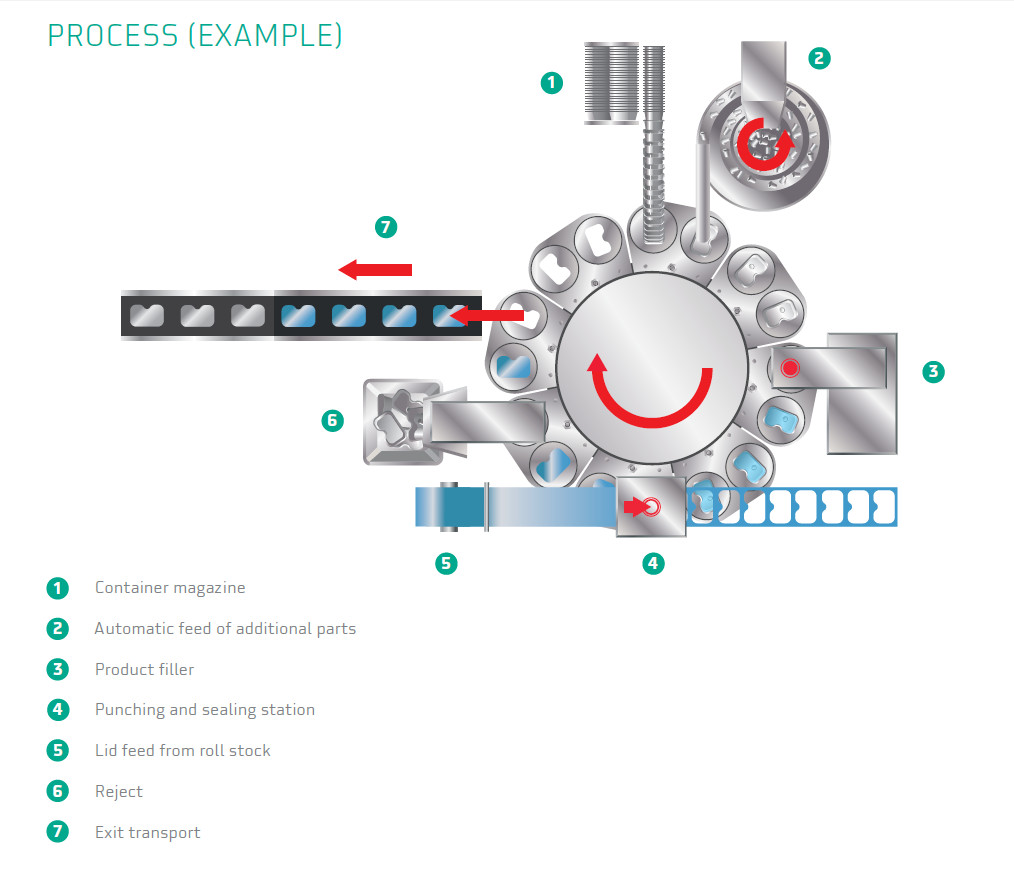

Rotary indexing table

– Sturdy rotary indexing table of hygiene design with 8 stations

– Free positioning of all functions

– Quick format insert change Container infeed / destacker

– Destacker for stackable containers with knives or sliders

– Manual direct loading into stack channels or through automated buffer system

– Sorting pot infeed and centrifugal transfer for non-stackable containers supplied in bulk (e.g. multi-compartment containers)

Punching and sealing

– Heat sealing or ultrasound sealing with material supplied on reels or in magazines

– Punching and sealing in a single process (one-stroke technology)

– Precision sealing station with closed force flux

– Inside-cut technology

Filling systems

– Dosing of powder products by means of volumetric screw conveyor or alternative filling system

− Dosing of liquids by means of various metering systems, including multiple filling head machines (peristaltic pump, piston dosing unit or time-pressure unit), e.g. for reagents

− Dosing systems generally with single lane operation

Control and operation

− Touch screen with process visualization

− Continuous monitoring of all relevant process parameters

− Control systems from Allen Bradley or Siemens Additional functions

− Marking systems with printing unit (inkjet, laser, etc.)

− Precision weighing by means of control weighing or filling level measuring with optical sensors

− Camera control system for quality assurance

− Assembly stations

− Other product-specific functions can be integrated on request.

Documentation

– Qualification documents (DQ, IQ, OQ) are available on request