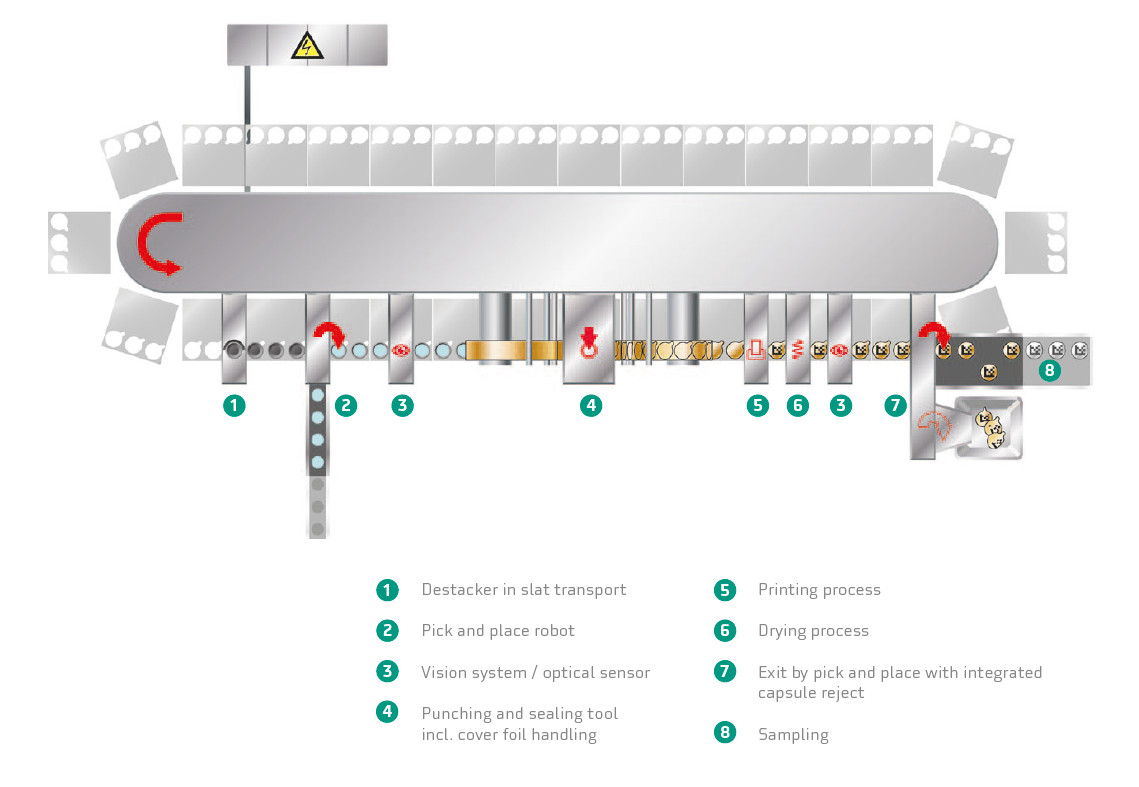

Transport Module

– Base frame with clearly separated product and drive elements

− Container transport on plates along high-precision spring steel belt in an oval rotary system

− Working area on transport plate 300 - 340 mm

− Excellent positioning accuracy by means of servo motor

− Functions can be freely arranged along the rear panel

− Integration of insulated area for processing under shielding gas, controlled ambient or laminar flow conditions

− Machine end designed for attachment of various exit options (pick&place, robot)

Container Infeed / Destacker

– Destacker for stackable containers with knives or sliders

− Direct loading into stack channels or through buffer system

− Sorting pot infeed and centrifugal transfer for non-stackable containers supplied in bulk

Punching / Sealing / Welding Module

– Hot-sealing or ultrasound technology with material supplied on reels or in magazines

− Punching and sealing in a single process (one-stroke technology)

− Ultra-precision sealing station with closed force flux

− Available with lifting and swivelling tools for easy cleaning and maintenance

− All tools with individual guide system and air spring support

− Sealing parameters can be individually set and monitored for each lane

Filling Systems

– Dosing of powdery products by means of volumetric screw conveyor or alternative filling system

− Dosing of liquids through various dosing systems (peristaltic pump, piston dosing device or time-pressure dosing system)

− Dosing systems designed for individual lane operation as standard Control Systems

– Weighing system with feedback signal to dosing unit for automated weight control

− Filling level monitoring with optical sensors

− Camera monitoring for functional and visual defects

Control / Operation

– Touch screen with process visualization

− Continuous monitoring of all relevant process parameters

− Control systems from Allen Bradley or Siemens

Additional Functions / Documentation

– Qualification documentation (DQ, IQ, OQ) available on request

− Marking systems by means of printing unit (inkjet, digital, etc.)

− Other product-specific functions such as robot or pick&place solutions for container assembly can be flexibly integrated

Coffee & Tea