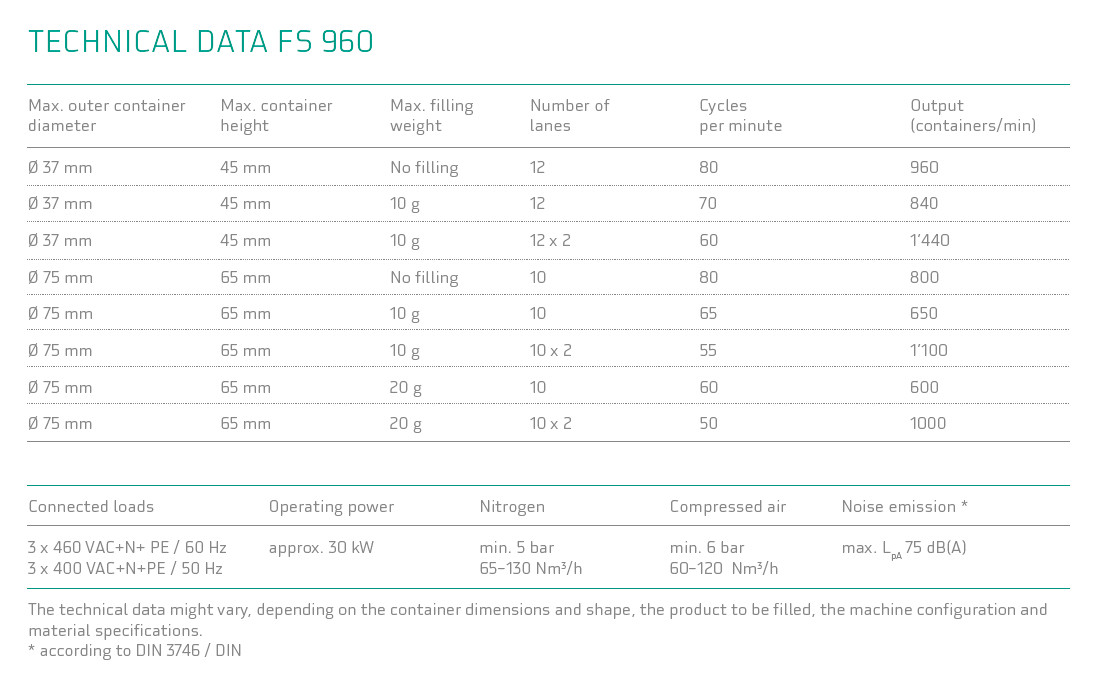

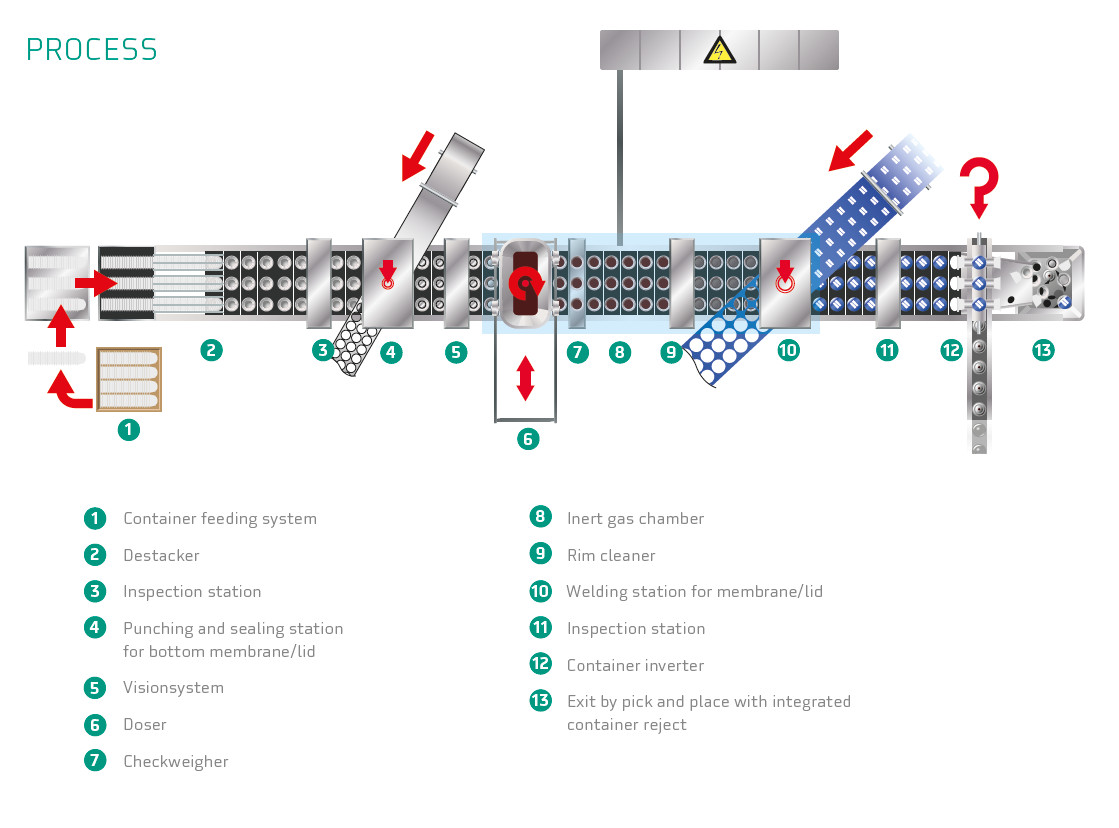

The FS 960 has been designed for low noise emissions, allows easy access to its components and meets the highest standards set for process hygiene. The FS 960 guarantees the highest process integrity thanks to a construction of standardized replicate components as well as uncompromised safety for people in contact with the machine.

Modular Transport system

- Base frame, adjustable in length

- Container transport by means of carrier plates driven on a maintenance-free and backlash-free timing belt

- Central drive unit with servo motor

- Working level ergonomically set at 900 mm over the ground

- Machine exit available with custom built interface to end of line equipment

- Laminar gas flow system for MAP applications, if required

Container destacker module

- Available systems: knife, slide or screw, depending on application

- Direct loading into tubes of stacking magazine or loading containers into buffering system

- Manual loading or automated container feeding

Punching/sealing/welding module

- Free-standing, module with closed force flow

- Punching and sealing in single step (one-stroke technology)

- Heat or ultrasound sealing for roll-stock materials or materials or components from magazines

- Integrated container lift below each station

- Swiveling upper tool suspension with lifting mechanism for easy access

- Individually guided tools with air spring support

- Temperature of each tool controlled individually

- Advanced Rychiger roll-stock handling system: 15–30% less waste in comparison with conventional systems

Filler module

- Free-standing module

- Accurate dosing for different dry powdery products, typically with augers.

- Individually controlled servo motors driving dosing shafts

- Product dose set from HMI

- Product dose automatic adjustment based on checkweigher signal

- Other, product specific dosing systems are available

Weighing module

- Free-standing module

- Piezoelectric load cells in each lane

- Feedback signal to dosing unit for automated weight control

- Ejection of non-conforming containers

- Tare weighing available Control equipment

- Standard automation systems from Allen Bradley or Siemens

Automated assembly/add-on functions

- Seamless integration of further product-specific functions over standardized interfaces, e.g. robotic container mounting, inspection systems, third-party filler.